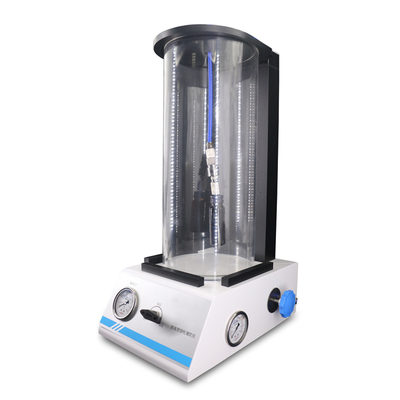

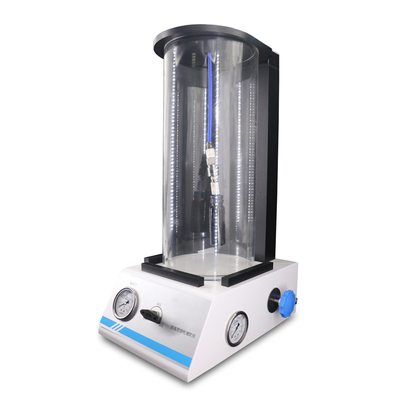

आईएसओ 13845 एएसटीएम डी2063 एएसटीएम एफ2095 बोतल कैप सीलिंग परीक्षक

बोतल के ढक्कन की सीलिंग परीक्षक का उपयोग गैस रिसाव को रोकने के लिए बोतलबंद और डिब्बाबंद पेय ढक्कन की सीलिंग प्रदर्शन को मापने के लिए किया जाता है, प्रभावी रूप से पैकेजिंग सील की गुणवत्ता को नियंत्रित करता है।

यह पीईटी बोतलों, कांच की बोतलों और डिब्बाबंद उत्पादों के परीक्षण के साथ-साथ मुकुट टोपी और पीईटी बोतल टोपी के सील प्रदर्शन को स्वतंत्र रूप से मापने के लिए उपयुक्त है।

बोतल के ढक्कन के प्रकार:

कार्बोनेटेड पीईटी बोतल पेय

मुकुट टोपी के साथ एल्यूमीनियम की बोतल

गैर कार्बोनेटेड पीईटी बोतल पेय

डिब्बाबंद पेय

मुकुट टोपी के साथ कांच की बोतल

एल्यूमीनियम पेंच टोपी के साथ कांच की बोतल

बोतल/कैन बंद करने के लिए योग्य सीलिंग मानक:

कार्बोनेटेड पीईटी बोतल पेय (जैसे, कोला): 1.0 एमपीए

गैर कार्बोनेटेड पीईटी बोतल पेय (जैसे, खनिज पानी, चाय): 0.2 एमपीए

क्रोन कैप/एल्यूमीनियम स्क्रू कैप के साथ कार्बोनेटेड ग्लास की बोतलें (जैसे, बीयर): 1.0 एमपीए

प्लास्टिक/एल्यूमीनियम स्क्रू कैप के साथ गैर कार्बोनेटेड ग्लास की बोतलें (जैसे, सोया सॉस, बाईज्यू): 0.2 एमपीए

कार्बोनेटेड डिब्बाबंद पेय (जैसे, बीयर, कोला): 1.0 एमपीए

गैर कार्बोनेटेड डिब्बाबंद पेय (जैसे, हर्बल चाय): 0.2 एमपीए

परीक्षक पानी में डूबे हुए नमूनों को दबाव में डालकर और सील पर बुलबुले के गठन का निरीक्षण करके लीक का पता लगाता है।

विशेषताएं और विनिर्देश:

दबाव स्रोतः संपीड़ित हवा या CO2

सकारात्मक-दबाव विधिः वैक्यूम आधारित परीक्षणों (<1 बार) की सीमाओं को पार करती है।

दबाव रेंजः 016 बार (1.6 एमपीए) ।

निर्माण: एनोडाइज्ड एल्यूमीनियम, स्टेनलेस स्टील और प्लास्टिक।

अंतर्निहित दबाव नियामकः अधिकतम परीक्षण दबाव को आसानी से सेट करें।

सुरक्षा विशेषताएंःदबाव राहत वाल्व, सुरक्षा वाल्व और बाल्टी ढक्कन सुरक्षा ताला। इंटरलॉक तंत्र

(परीक्षण बंद हो जाता है यदि पानी का बाल्टी बंद नहीं है) निकास बंदरगाहों के माध्यम से तेजी से गैस वेंटिलेशन (स्टार्ट करने के लिए ढक्कन बंद किया जाना चाहिए; उठाने ढक्कन तुरंत depressurizes) ।

सटीक प्रवाह नियंत्रण: समायोज्य दबाव दर (5 ¢ 60 सेकंड 1 एमपीए तक पहुंचने के लिए) ।

उच्च संवेदनशीलता और सटीकताः

| प्रेशर गेज रिज़ॉल्यूशन |

0.05 एमपीए. |

| गेज रेंज |

0°1.6 एमपीए. |

| अधिकतम नमूना आयाम |

330 × 150 मिमी (एच × डी) |

| आयाम |

320 × 380 × 720 मिमी (एल × डब्ल्यू × एच) |

| शुद्ध भार |

15 किलो। |

परीक्षण का सिद्धांत:

क्लोजर सील परीक्षक का प्रयोग पीईटी पेय बोतलों के ढक्कनों के सील प्रदर्शन की जांच करने के लिए किया जाता है। परीक्षण के दौरान नमूना एक पानी के टैंक में रखा जाता है,और सामान्य वायुमंडलीय परिस्थितियों से परे आंतरिक दबाव बढ़ाने के लिए नमूना के ऊपरी भाग में गैस की एक निश्चित मात्रा इंजेक्ट की जाती है, इस प्रकार नमूना के बंद होने की सील की अखंडता का परीक्षण किया जाता है।

योग्य सील प्रदर्शन के साथ नमूनों के लिए वे रिसाव के किसी भी संकेत को दिखाने के बिना अतिरिक्त दबाव का सामना करेंगे।कैप क्षेत्र से बुलबुले उभरेंगेद्रव लीक के बजाय गैस लीक का पता लगाने से माप संवेदनशीलता को अधिकतम किया जाता है।

परीक्षण नमूना के अंदर दबाव एक दबाव घटाने के माध्यम से नियंत्रित किया जा सकता है, जबकि दबाव गैस के प्रवाह दर एक प्रवाह नियंत्रण वाल्व के माध्यम से समायोजित किया जा सकता है। गैस के दबाव को विनियमित करके,ऑपरेटर अधिकतम दबाव निर्धारित कर सकते हैं जो सील या कंटेनर रिसाव होने से पहले सहन कर सकता हैगैस प्रवाह दर को नियंत्रित करके, एक अधिक सटीक आंतरिक बोतल दबाव स्थापित किया जा सकता है,ऑपरेटरों को उस दबाव मूल्य को पढ़ने की अनुमति देता है जिस पर रिसाव होता है और इस प्रकार सील विफलता की गंभीरता का आकलन करता है.

ZL-9025C क्लोजर सील परीक्षक में कई सुरक्षा सुविधाएं शामिल हैं, जिसमें एक सुरक्षा वाल्व, उपकरण कवर पर तेजी से गैस निकास बंदरगाह, एक सुरक्षा ढक्कन लॉक, एक दबाव घटाने वाला,और परीक्षण नमूनों को डुबोने के लिए एक बेलनाकार पानी टैंक.

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!